Anti Rust Paint & Spray: How ZRC Works

ZRC is a premier anti corrosion cold galvanizing compound renowned for its exceptional protective properties. Engineered to resist rust and corrosion even in the harshest environments, ZRC forms a robust barrier against moisture and chemicals. Trusted by industries worldwide for corrosion protection, its advanced formula ensures long-lasting protection for various metal surfaces, making it a preferred choice for corrosion prevention strategies.

How Our Corrosion Protection Spray and Paint Works

Dried Film Zinc Percentage

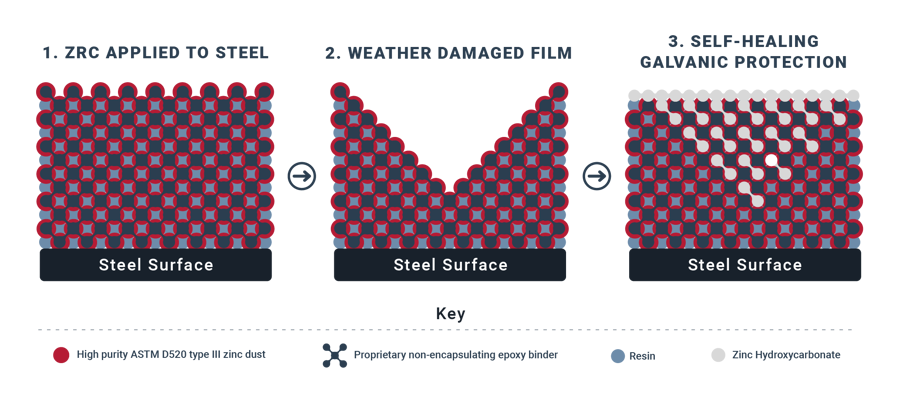

This illustration shows the difference between the true galvanic protection of ZRC® and Galvilite® and other types of coatings. The difference is made possible by ZRC's high zinc content (95% by weight in the dried film) of "ultra-pure" zinc dust (ASTM D520 Type III) and proprietary, non-encapsulating binder. This unique combination provides a self-healing galvanic film that is impossible for others to match.

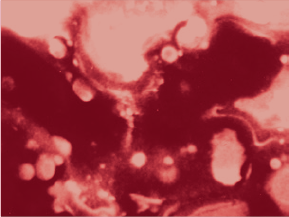

Bad: Low Percentage Zinc Coating

In a “zinc-rich primer”, an electron microscope photo shows wide gaps between zinc particles filled with insulating resin which blocks the flow of electrical current. There’s no galvaning action for protection!

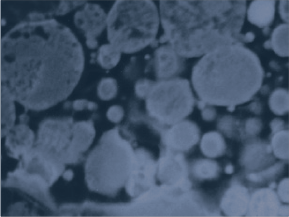

Good: ZRC 95% “Ultra-Pure” Zinc

An electron microscope photo shows zinc particles in close contact with each other allowing the flow of electrical current; that’s true galvanic corrosion protection!

Dried Film Zinc Percentage

This illustration shows the difference between the true galvanic protection of ZRC® and Galvilite® and other types of coatings. The difference is made possible by ZRC's high zinc content (95% by weight in the dried film) of "ultra-pure" zinc dust (ASTM D520 Type III) and proprietary, non-encapsulating binder. This unique combination provides a self-healing galvanic film that is impossible for others to match.

Bad: Low Percentage Zinc Coating

In a “zinc-rich primer”, an electron microscope photo shows wide gaps between zinc particles filled with insulating resin which blocks the flow of electrical current. There’s no galvaning action for protection!

Good: ZRC 95% “Ultra-Pure” Zinc

An electron microscope photo shows zinc particles in close contact with each other allowing the flow of electrical current; that’s true galvanic corrosion protection!

The Importance of Zinc in Corrosion Protection

"Ultra pure" Zinc dust is integrated with our trade secret organic binder. This binder allows the zinc particles to remain in contact with each other so that the ZRC is anodic to the base metal, thereby imparting true galvanic action.

Frequently Asked Questions

What is ZRC?

ZRC is the brand of the highest quality zinc-rich coatings on the market containing 95% "ultra-pure" zinc dust by weight in the dried film. They bond to clean iron, steel, or aluminum to provide maximum protection against rust and rust creepage through "galvanic action". The ZRC product lines consist of ZRC®, GALVILITE®, ZRC®221, and ZERO VOC ZRC. ZRC Worldwide has been registered to the International Organization for Standardization ISO 9001 Series Standards for Quality.

What are the major uses for ZRC's zinc-rich coatings?

ZRC is widely used to prevent rust and rust creepage in place of hot-dip galvanizing, as well as the following major uses:

-

High-performance base coat for a variety of topcoats

-

Repair of damaged hot-dip galvanizing, Galvalume®, and zinc metalizing

-

Regalvanizing worn hot-dip galvanizing, Galvalume®, and zinc metalizing

-

Repair of weldments on galvanized material

-

Repair of damaged inorganic zinc coatings.

How does ZRC work?

Is ZRC a paint?

Is ZRC equivalent to hot-dip galvanizing?

Other FAQs

Where can I buy ZRC?

You can buy ZRC directly from our online store. One of the most significant benefits of making a purchase online is convenience. You can shop for your needed corrosion prevention products from anywhere at any time, without having to leave your office or home. Our online store eliminates the need to physically visit a retailer, saving you time and effort. Not only that, you can have ZRC shipped anywhere, even somewhere without representation from a distributor. You can also Call our Customer Service Department 1-800-831-3275.

ZRC products are non-hazardous for ground transportation, so they can be shipped by UPS as well as a common carrier, factory direct or through our worldwide network of authorized distributors. No minimum order requirements for factory direct shipments paid by MasterCard, Visa, American Express, COD or Prepaid orders and strive to ship within 48 hours of receipt of order.

It is the only cold galvanizing compound on the market that is ISO 9001 registered, U.L. approved and recognized as an equivalent to hot-dip galvanizing. Its low VOC levels are accepted in all 50 states and it is non-hazardous for ground transportation.

As well, you can buy ZRC from your nearest dealer. Our distributors have in-depth knowledge of the products they sell. Shopping online can feel a bit overwhelming if you’re not sure exactly what you’re looking for. Which ZRC product is right for your project? Do you want aerosol spray or brush-on paint? A dealer is able to provide detailed information and guidance on product selection, use, and maintenance. You can find one closest to your area here on our dealer locator page.

What specifications does ZRC meet?

ZRC meets and exceeds Fed. Spec. DOD-P-21035a, The Department of Defense galvanizing repair spec.

ZRC meets and exceeds military specification Mil-P-26915a, the USAF zinc-dust spec.

ZRC may be used under military specification Mil-P-26433 for tower protection - temperate & arctic.

ZRC passed the Preece Test ASTM Des. A239 for hot-dip galvanizing.

ZRC passes 3,000 hours of salt spray testing without failure (ASTM-B117-73).

ZRC resists intermittent dry-heat temperatures up to 750 ° F.

ZRC meets and exceeds Canadian Government Spec. 1-GP-181a for hot-dip repair.

ZRC meets and exceeds ASTM Des. A-780 (standard practice for repair of damaged hot-dip galvanized coatings).

ZRC compound is authorized for food contact under Federal Regulation 21 CFR 175.390 for use as a coating on bulk re-usable containers intended for storing, handling and transporting food.

ZRC compound is recognized under the component program of Underwriter's Laboratories, Inc. MH7035, and is retested by U.L. every year.

ZRC compound is chemically accepted by the U. S. Department of Agriculture. It may be used in processing or storage areas for meat or poultry food products prepared under federal inspection.

ZRC meets and exceeds SSPC-Paint 20 ( Specification for zinc-rich primers)

ZRC meets and exceeds SSPC-Paint 29 ( Specification for zinc dust sacrificial primer, performance-based.)

ZRC meets and exceeds the requirements of Specification ISO 8179-2, Zinc-Rich Paints

Contact ZRC About Corrosion Protection

Don't wait until rust and corrosion cost you money! Here at ZRC Worldwide, we developed the technology behind zinc-rich coating over 70 years ago, and we continue to lead the industry today. Act now to apply cold galvanizing compound and fortify your metal assets against rain, humidity, wind, freezing temperatures, and other weather that leads to corrosion. You can reach out to our team with any additional questions you may have. Join countless others who trust ZRC as an industry leader in metal surface protection.

Quotes from Our Customers

It’s no secret we’re the industry-leading solution that lasts. Here’s what our customers have to say.

Because of my experience in the field with this product, I always recommend ZRC in corrosive applications. I've used ZRC to regalvanize radar towers and catwalk gratings for the Navy at the base in Winter Harbor, Maine. I also used it on metal roofs and on salt water cookers at a canning company. In all cases, it has provided five years or more of rust-free protection.

Roy Love | President, Loves Painting

Of all the painting systems I have used to protect ironwork in the past ten years, ZRC topcoated with epoxy works the best — even in highly corrosive, humid environments.

Doug McLean | President, McLean's Blacksmithing, Inc., Galveston TX

The main advantage of ZRC was that it allowed us to provide galvanized protection on site without delays to the project. Another important factor in specifying ZRC is its true cathodic action. With the volume of heavy traffic passing through the transit shed doors, it is likely they will be scratched. ZRC should provide zinc protection even when the doors are scratched to bare metal.

Sofia Rovira | Principal and executive vice president, DSA; Director, DSA's Building Design Services

-1.png?width=400&name=ZRC%20Website%20image%20Can%20(1)-1.png)